The manufacturing of chemicals is an astringent process. It needs a strong team in the plant and in the lab to be able to assure customers with constant quality products. The role of each employee, from the operator, the Quality Control technician, the plant engineer as well as the Quality Control supervisor is critical. In order to have each link of that chain efficient and strong, Quality Circles can be implemented.

Quality Circles (QC) started in the 50’s in Japan in order to re-establish Japan as a business leader. Since then, the idea of “gathering the wisdom of the people” (translation of Circles from Japanese) has since been used around the world with significant success.

The Circles are composed of volunteer members who meet regularly to identify and solve work-related problems. The solutions are then implemented under management approval. These Circles are an additional tool to quality practices already in place in the organization. Quality Circles allow employees from the whole company to create a new way of solving issues by encouraging awareness, self-development and team-building. The members focus on having a different approach to traditional cost savings, waste reduction or process improvement.

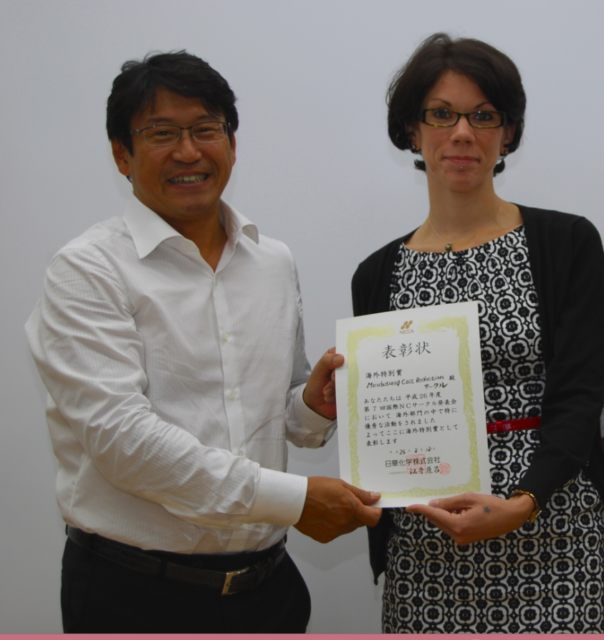

NICCA Chemical held its 7th Quality Circle Meeting this past August. Every subsidiary met at the headquarters in Fukui, Japan and presented the QC projects they have been working on for the past two years. This meeting is an opportunity for all plants to brainstorm about how to improve quality in NICCA Group and how to provide the same quality products to customers around the world. Once again, NICCA USA has been recognized for its contribution toward quality and its creative way of problem solving. NICCA USA was awarded the second place of the 7th Quality Circle Meeting.

Congratulation to all the QC Team and to all the employees for a great effort in implementing the new solution!