Process Improvement

In any industrial process, one always hears the phrase, “Process Improvement.” Other names you may be familiar with are: Continuous Improvement, Kaizen, Lean, 5S, etc. What is “Process Improvement” anyways? According to the Cambridge online dictionary:

Process Improvement

The job of examining the processes used in a company, department, project, etc. to

see how they can be made more effective.

In reality, process improvement usually boils down to: what changes/improvements can be made to this process that will reduce non-value added steps and outputs, increase profitability, and maintain or improve quality? Common themes to examine when referring specifically to manufacturing process improvement would be: saving time, reducing problems, using less energy, using less water and other resources, and generating less waste. Although some processes can seem overwhelmingly complicated, do not let that discourage you from approaching process improvement projects and tasks. With thought and time, you can make improvements without any knowledge of a specific skillset or tool. Process improvement just requires a thorough understanding of the process to be examined and a little innovation.

*Since NICCA USA is a textile chemicals manufacturer, I will use our business as an example, sticking strictly to production process improvement.

Producing more with less

The saying that less is more, isn’t always true; sometimes less compromises quality. However, by being innovative, you can find ways to reduce without compromising quality. In particular, textile chemical production and application require a lot of water – dye baths, water-based chemical solutions, rinses; a lot of energy – high temperatures, chemical manufacturing, hot fabric dryers, textile mill equipment; and a lot of time.

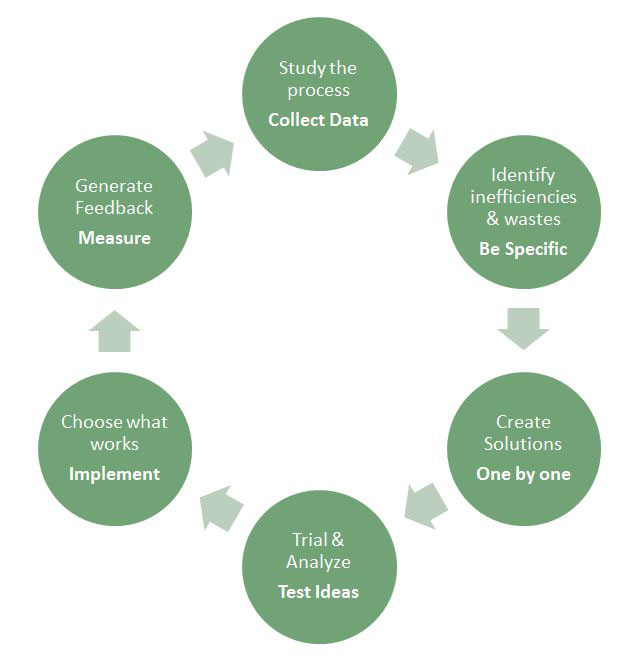

Step 1: Study the Process

Examine these processes. Look at each step specifically, collecting data to generate real conclusions on the current process situation. Spend time with the process and the people who operate it on a daily basis. Ask questions and gather feedback.

Step 2: Identify Inefficiencies and Wastes

Where are the inefficiencies? Where can you apply process improvement? Are there ways you can recycle water, chemicals, or fabric to generate less waste? Can you re-engineer your process using chemicals that work together more effectively to use less energy and be watersmart? Is your equipment running at premium electrical efficiency, or are there ways you could better control power usage? Is there a better method to complete a certain step? Cross-examine each step with these types of questions until you find specific points to set your focus.

Step 3: Create Solutions

Once you’ve identified some key areas to attack, create process improvement solutions. Although generating solutions is definitely possible individually, it is best to do this process as part of a group discussion where innovation and feedback can be shared. Don’t be afraid to think outside the box. Process improvement almost requires that type of thinking.

Step 4: Trial and Analyze

Now that you have some ideas for process improvement, start running trials and tests to analyze solution effectiveness. Not every idea will be a success, but if you remain at the drawing board and keep thinking, you will produce results. Schedule lab trials, schedule pilot trials, and test the results. Take advantage of others’ expertise and equipment; utilize outside resources to help develop advanced solutions where necessary.

Step 5: Choose What Works

If you’re satisfied with the results from initial trials and testing, start implementing your successful solutions on the production scale. This may take some time, but be patient. Some processes are very difficult to change and some process improvements are difficult to implement.

Step 6: Generate Feedback

Measure the results from implementing your solutions on a production scale. Translate these results from time, energy, and resources saved into dollars saved to better present the information so that others can easily understand. Based on these results, ask yourself some questions: did you achieve your desired results? Would you do anything differently? How will this process improvement affect other processes downstream?

Of course, this isn’t a strict rule book for making process improvements, merely just a basic explanation. Do research! There are many different techniques, skills, and methods used to improve processes. Process improvement is not only for manufacturing, but also an unlimited number of other applications.